Additional Water Means Higher Yields

Due to the intensive mixing of flour and ingredients, AFS industrial mixers allow for additional hydration rates for most batter and doughs. Typical customers are able to add 5-10% additional water to the recipe.

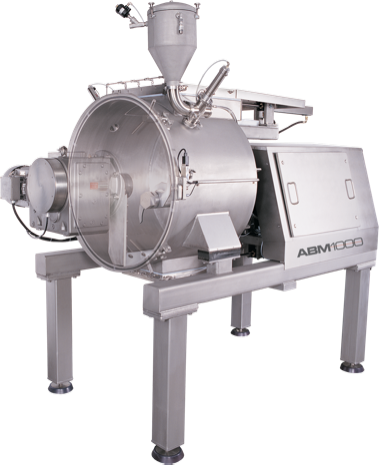

The ABM’s mechanical mixing action is so intense that it can expose more surface area of the flour particles to the recipe water, enabling the flour to absorb more water and increasing the hydration rate. This moisture is “bound up,” meaning sticking can be controlled and shelf-life isn’t negatively impacted.